New Insights, a No-Regrets 3D Printing Guide, and the Best Reads on the Project Site

If you run a fashion or craft SME in Romania, you’re probably juggling the same three pressures every day: customers want originality, they expect better sustainability, and they’re drawn to products with a genuine “made with meaning” story. At the same time, you’re working with real constraints like tight budgets, short timelines, and small teams doing a lot.

That’s exactly why we’re sharing the latest progress from CRAFTIT4SD in Romania. Not as hype or a trend report, but as practical learning you can actually use. In the North-East region, especially, where textiles, crafts, and fashion are deeply tied to local identity, innovation only sticks when it respects reality.

In this post, we’ll walk you through three updates from Reginnova NE’s perspective. First, our new in-depth research on what 3D printing looks like for Romanian TCLF SMEs right now. Second, a short follow-up guide that shows how to test 3D printing “with no regrets.” Third, a curated reading path from the official CRAFTIT4SD website—because the articles there are genuinely worth your time.

A quick refresher: what is CRAFTIT4SD, and why does it matter here?

CRAFTIT4SD is an EU-funded project built to help the cultural and creative sectors, including fashion and crafts, move faster and more confidently toward the green transition. The approach is simple and powerful: cross-sector collaboration, supported by digital tools and shared learning.

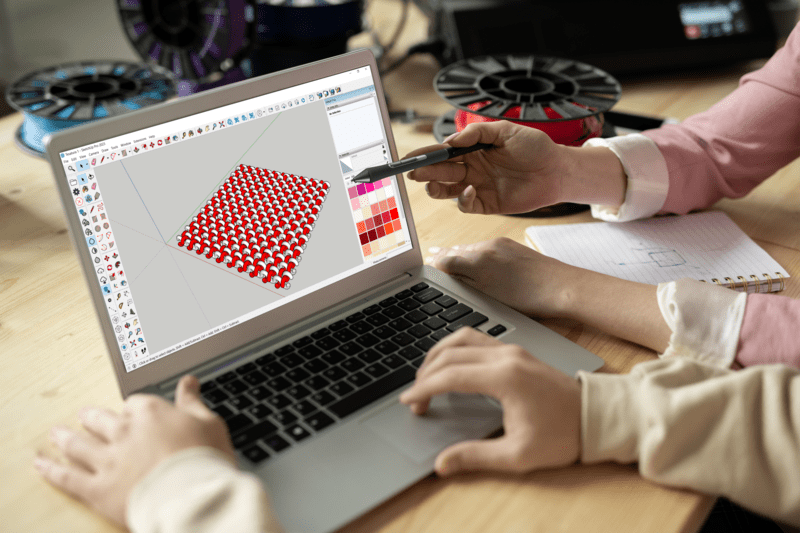

In Romania, a key focus is Pilot 1: TUIASI / Reginnova. This pilot explores additive manufacturing and 3D printing in the context of sustainable crafted capsule collections. Just as important, it looks at how that learning becomes regional capability: skills, partnerships, and business-ready know-how that SMEs can apply.

This is what makes the work relevant. It’s not “innovation for innovation’s sake.” It’s capability-building, designed for the whole ecosystem, SMEs, education, clusters, and practitioners, so experimentation becomes safer, more structured, and easier to translate into results.

With that context in place, here are the three updates.

If you take one thing from this update, let it be this: the article will help you answer a straightforward question: Where does 3D printing actually fit in my business today, if it fits at all?

Update #1: Our in-depth research is out, and it reflects the Romanian SME reality (not the hype)

We wrote “From tradition to innovation by integrating 3D printing and sustainable craft development” because the conversation around 3D printing in fashion often swings between extremes. One side promises a revolution. The other says, “Nice idea, but not realistic.” Romanian SMEs deserve better than extremes. You deserve clarity: where the technology fits today, where it doesn’t, and what needs to be true for it to create value.

That’s why the article combines a regional lens from the North-East with insights from interviews with nine TCLF SMEs, alongside expert perspectives from Radu Firicel (CraftIT4SD pilot specialist) and Kjell Neumann (Hanze Makerspace coordinator).

Here’s what came through clearly. Interest is real, but adoption is cautious. And honestly, it should be. Many businesses are open to experimenting, yet they want three things before committing: confidence in quality, a cost profile they can control, and training that makes the tools usable in everyday work.

The expert insights reinforced that this caution isn’t “resistance.” It’s smart decision-making. Firicel highlights a practical point that gets overlooked: most FDM printers weren’t designed with textile workflows in mind. As a result, the gap between a cool demo and a reliable process is often bigger than people expect. Success comes from understanding materials and building repeatable workflows.

Neumann adds a second reality check. 3D printing can be powerful, but it doesn’t automatically win on scale or unit economics compared to established industrial processes. For SMEs, the early value tends to appear in rapid prototyping, small-series differentiation, and customisation, not in mass production.

Update #2: We turned the research into a short “no-regrets” guide for SMEs

Once the research went live, a follow-up question kept showing up:

“How do I try this without risking my cash flow or my reputation?”

That’s why we published a shorter, tactical follow-up: “3D Print With No Regrets for Fashion and Crafts SMEs.”

This piece is built for action. It’s written for founders, atelier leads, and product teams who want to explore 3D printing without turning it into an expensive side project that drifts, stalls, and never translates into product value.

The core principle is simple: don’t try to “adopt 3D printing.” Pilot one use case. Keep it narrow enough to test properly and quickly. Depending on your category, that might mean rapid prototyping, textile enhancements, leather tooling (such as embossing dies), or footwear components using flexible polymers.

The guide also emphasises a decision that can save Romanian SMEs real money: access before ownership. If your main reason for buying a printer is “we need to experiment,” start with shared access instead, through a lab, a makerspace, or a university partnership. This aligns closely with the broader aims of Pilot 1, which focuses on capability-building through skills, training, and ecosystem partnerships, so learning becomes structured rather than chaotic.

Most importantly, the no-regrets approach protects your quality standards. In fashion and crafts, printing something is rarely the hardest part. Printing something you can repeat, test, and integrate into your workflow, that’s where the work is.

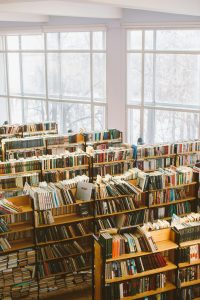

Update #3: The CRAFTIT4SD website is a goldmine. Here’s what we’d read first

If you haven’t explored the official CRAFTIT4SD website recently, it’s worth going back. The project isn’t only documenting pilots. It’s building a growing library of articles that are readable, relevant, and genuinely useful for SMEs.

At a high level, the mission is ambitious: activate Europe’s craft heritage, revitalise it towards the green transition by building on the rich cultural heritage and strong creative traditions which underpin the European CCSI.

What makes the site valuable in practice is the content itself. If you want a simple reading path tailored to fashion and craft SMEs, start with pieces that explore adoption and mindset, then move into the articles that treat sustainability as more than materials and packaging, and look at the climate impact of business models. If compliance and regulation feel like a looming burden, read the pieces that reframe legislation as a value-creation opportunity rather than a distraction.

To connect everything back to what we are doing at a regional level, bookmark the Pilot pages. It’s the clearest overview of what’s being developed in Iași and other regions across Europe and why it matters for regional capability-building.

What these updates mean for Romanian fashion and craft SMEs

Together, these three updates form a practical learning path.

The research article gives you the landscape: what Romanian SMEs are thinking, what experts see as realistic, and which use cases have the strongest credibility today.

The no-regrets guide gives you a way to move forward without overcommitting: how to run a structured pilot, control costs, and protect quality while you learn.

And the CRAFTIT4SD website gives you ongoing perspective: an evolving library that helps you stay informed, inspired, and connected to a wider European conversation about sustainable fashion and craft innovation.

You don’t need to “transform” overnight. You need one smart experiment; one that you can explain, measure, and repeat.

Final thought: what’s your “no-regrets” experiment for 2026?

If you’re new to the topic, start with the in-depth research and then move to the no-regrets guide. If you’re already experimenting, use the CRAFTIT4SD website to keep your thinking sharp and your options broad. Don’t forget to check out the CRAFTIT4SD Linktree for more valuable content.

And here’s the question we’d genuinely love to hear more Romanian SMEs answer openly and honestly:

What would a no-regrets innovation experiment look like in your atelier or workshop, one that protects your quality and your story, while still pushing you forward?

Tell us what you make – garments, leather goods, craft objects, footwear, or home textiles- and what your biggest constraint is right now (budget, materials, skills, production capacity), and we can point you toward the most relevant reads and pilot-friendly next steps, grounded in the work happening through CRAFTIT4SD in Romania.